ECOCELL principle

Modelled on Nature

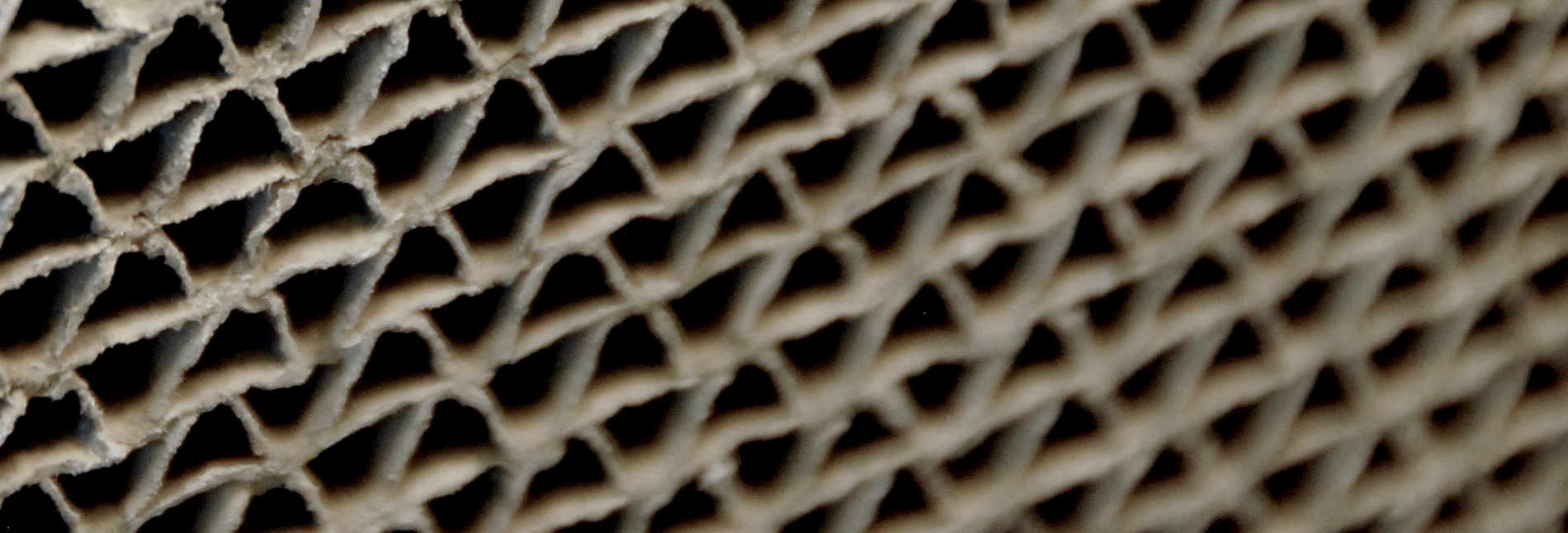

Nature provides perfect role models. A well-known example is the bee’s honeycomb. ECOCELL CONCRETE-HONEYCOMB was developed in accordance with the laws of nature.

- The almost exclusive use of renewable raw materials derived from the recycling cycle of waste paper and cardboard, with emphasis on corrugated cardboard.

- A specially developed mineral coating petrifies the raw honeycomb structure.

- The delicate honeycomb structure remains intact – this makes the building material fire resistant and affords excellent thermal insulating properties.

- In combination with panels made of wood or other materials, a highly resilient sandwich construction is created – the ECOCELL FAST-CONSTRUCTION-SYSTEM and the ECOCELL-US-BUILDING-SYSTEM.

Primary raw material: corrugated cardboard

- Corrugated cardboard is the number one packaging material in the world and is readily available on the global market.

- The existing machinery of the corrugated cardboard industry can be converted for the production of ECOCELL products in a short time by simply changing the cylinders and aggregate.

- The global availability of corrugated cardboard in terms of material and production facilities, vastly eases production and development of the honeycomb in decentralized production sites.

Lightweight composite technology

Lightweight composite technology has already revolutionized industries such as aerospace or car manufacturing. It is also bound to push for innovation in the construction industry.

The composite materials consist of a middle layer of honeycomb and an upper and lower liner layer. The honeycomb itself represents at least three quarters of the total volume. For ECOCELL products this means:

- Large cost savings due to low material costs.

- ECOCELL CONCRETE-HONEYCOMB consists 90% of air chambers.

- Reduction and substitution of CO2 through using OSB, wood or bamboo panels as a composite material.

- The ECOCELL CONCRETE-HONEYCOMB is three times lighter than wood and 12 times lighter than concrete.

ECOCELL – Solutions for global problems

Global MEGA trends such as demography, urbanization, climate change and an increase in the demand for energy will change the world of tomorrow. These factors will have an enormous influence on the building sector. ECOCELL has developed a disruptive technology that is already counteracting those trends today:

- ECOCELL’s low-cost raw material, derived from recycled paper, is globally the cheapest construction material.

- The ECOCELL FAST-BUILDING-SYSTEM cuts construction times by up to 70%.

- ECOCELL works with resource-saving secondary raw materials.

- ECOCELL reduces and substitutes CO2 emissions, even beyond the product life cycle.

ECOCELL – Added value

- Seismic safety:

The first thermal insulation with a structural function. ECOCELL CONCRETE-HONEYCOMB enables earthquake-resistant construction. - Thermal insulation:

The delicate air chambers in the honeycomb also provide “free” thermal insulation. - Energy independence:

ECOCELL houses can be completely (roof and façade) covered with photovoltaic panels. The overall energy concept provides independence from rising energy costs.