ECOCELL MANUFACTURE AND TRADE LICENSE

ECOCELL SELLS SUSTAINABILITY

The ECOCELL CONCRETE-HONEYCOMB is by far the cheapest and fastest producible building material.

And at the same time, the CONCRETE-HONEYCOMB is the first insulation that can be statically used in a composite.

The new construction and building materials, produced out of the CONCRETE-HONEYCOMB, will mark a new era for the construction and the building industry. Newly designed construction material such as:

- the ECOCELL HONEYCOMB-CONSTRUCTION-BOARDS

- the ECOCELL HONEYOMB FLOOR SCREED

- the ECOCELL ECO-SOLAR-ENERGY-FACADE

- the ECOCELL PARTITION WALLS

- the ECOCELL-FAST-BUILDING-SYSTEM

- the ECOCELL-US-BUILDING-SYSTEM

ECOCELL is living an active CLIMATE PROTECTION and solves many other Global Problems:

- causes no CO2 emissions, but reduces greenhouse gases

- enables energy self-sufficient living

- avoids petroleum-based substances

- lives the circular economy

- allows multiple use of building components

- needs neither sand nor gravel

- avoids unnecessary transports

- enables affordable living

- solves the lack of craftsmen and skilled workers

Because together with low-cost housing, sustainability is a fundamental part of ECOCELL’s philosophy.

CORRUGATED CARDBOARD MACHINES ARE AVAILABLE WORLDWIDE

The basic material to produce the ECOCELL CONCRETE-HONEYCOMB is corrugated cardboard. ECOCELL has three different, patented processes of converting corrugated cardboard into raw honeycomb in only one single process. The honeycomb structure, made of 100% recycled paper, consists mainly of air. In order to avoid unnecessary costs and environmental pollution caused by transport, further processing into ECOCELL CONCRETE-HONEYCOMB should preferably take place directly behind the cardboard plant.

The ECOCELL CONCRETE-HONEYCOMB can then be delivered as a semi-finished product to board producers or distributors or further processed at the same location to ECOCELL HONEYCOMB-CONSTRUCTION-BOARDS or standard components for the ECOCELL FAST-BUILDING-SYSTEM.

ECOCELL is in charge of three different patented processes, to produce the raw honeycomb required for the CONCRETE-HONEYCOMB in only one process directly out of corrugated cardboard sheets.

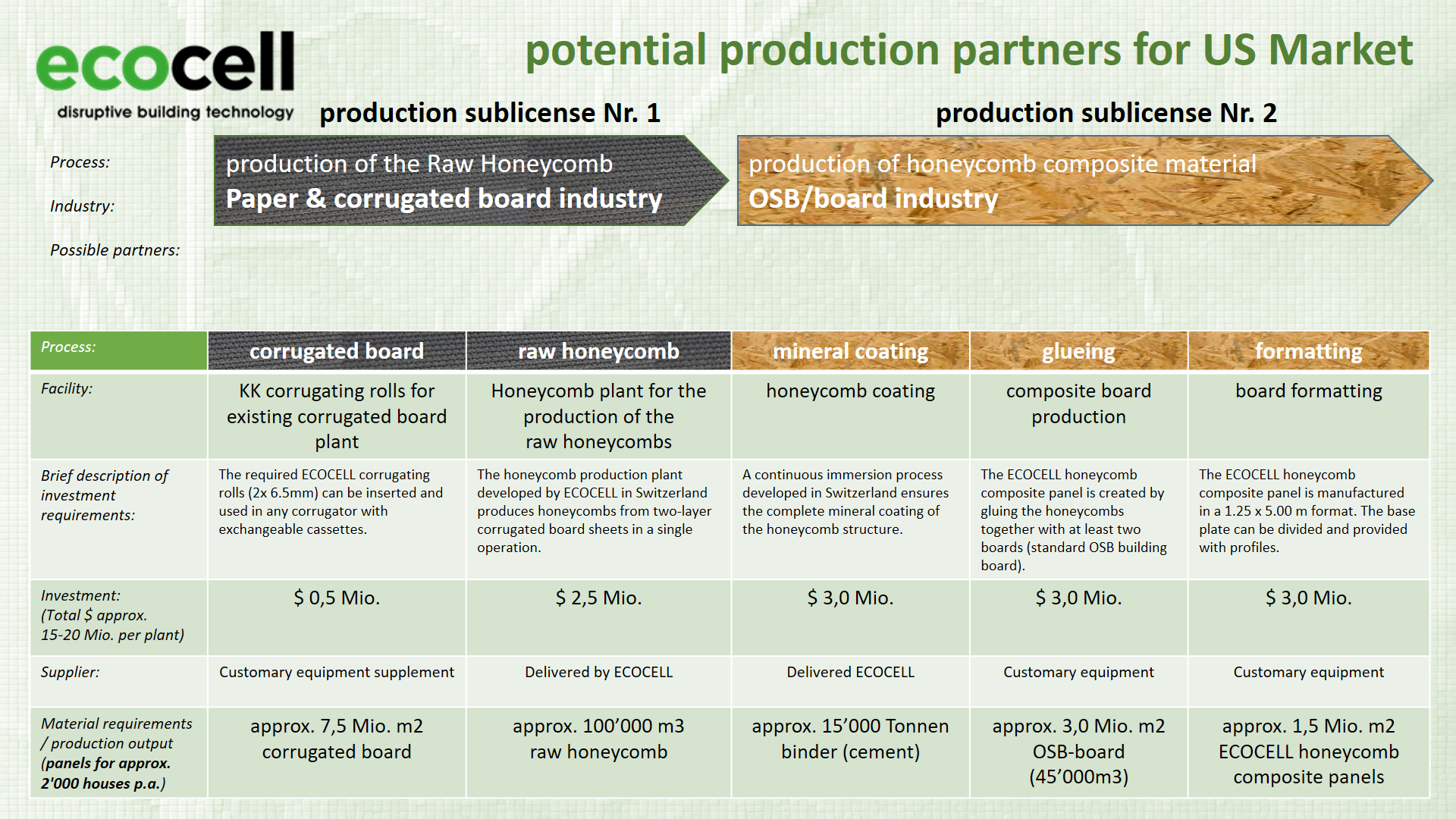

A production site with a capacity of ECOCELL building elements for 2’000-4’000 houses requires

7’500’000 m2

of corrugated cardboard per year (four-layer KK-flute). The special corrugating cylinders required for this purpose are primarily supplied by ECOCELL.

NEW BUSINESS FIELD FOR THE PAPER AND CORRUGATED CARDBOARD INDUSTRY

ECOCELL can show the paper and cardboard industry a new, so far unknown business field and can therefore help to optimize the plant output.

DECENTRALIZED PRODUCTION

In order to avoid unnecessary and costly transports, the production sites for the production of the ECOCELL CONCRETE-HONEYCOMB should be located directly behinde or in the closest neighbourhood of corrugated cardboard plants.

Corrugated cardboard producer – ask now for a production-license!

ECOCELL License Reservation

A pre-emptive right for an ECOCELL manufacturing and/or distribution license for a country or a certain region can be arranged by a shareholding at ECOCELL Technology AG.

The participation can take the form of the direct buying of shares or the subscription of shares in one of the ongoing capital increments.

First machine (Swiss-made prototype) to produce the RAW-HONEYCOMB-STRUCTURES from corrugated cardboard sheets in one single operation using a process patented by ECOCELL.